Jaw Crusher Machine and Their Types

Jaw Crusher

Probably the earliest forms of crushers were enormous stones utilized by people to over and over pound rocks put upon a blacksmith's iron (a hard fixed surface); the items produced using this pounding activity were moved by pack creatures or people in sacks. By and large, mining errands were unquestionably work escalated, and the created mined items were correspondingly costly.

The main devices accessible to breakdown mineral were a bore, demolition hammer, or a pickaxe (and the determination of a couple of enthusiastic specialists). Most of metal measuring and squashing activities were finished by hand until part of the way through the nineteenth hundred years. As of now, water controlled trip hammers began helping excavators; it was generally the start of the modern upset.

During the modern unrest, business mining began seeing the utilization of explosives like black powder at the core of many mining tasks; this mining technique is known as 'impacting' and it prompted ever bigger amounts of rock and minerals being freed. Steam scoops were the following apparatus to alter the mining business. Over the long run, bigger machines and further developed mining procedures began making it conceivable to free altogether bigger parts of metal.

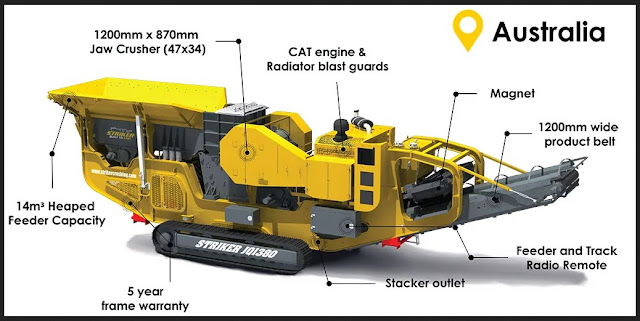

Mobile Jaw Crusher

The interest for mined minerals and other mined results has not diminished throughout recent years. To guarantee supply could fulfill need, various pulverizing and it were developed to convey machines. Without concurrent advances inside the fields of comminution and conveying, it could never have been feasible to mine and convey materials securely and productively (even current transports can't convey single blocks of material weighing numerous tons).

Practically all quarry and mining tasks today utilize crushers to decrease the size of bigger materials; free (more modest) measured materials don't regularly need a devastating stage. While mining harder stone, jaw crushers, cone crushers, as well as gyratory crushers are typically utilized.

Partaking in this article? Then, at that point, make certain to look at our Designing Video Courses! Each course has a test, handbook, and you will get a declaration when you complete the course.

Purpose of Material Crushers (Size Reduction)

A crusher is a machine intended to lessen the size of enormous rocks to more modest rocks, rock, sand, or rock dust; this is fundamental for proficient vehicle of the item through transports and so on. Crushing is the first of many stages that lead to division of the mineral(s) from the waste (gangue) material. Squander material can be disposed of or reused permitting the mineral rich item to be additionally handled at the primary plant.

Different sorts of crusher and mineral separator might be utilized relying on the throughput, hardness, and properties of the mineral being handled. In all cases, the devastating stage is basically accomplished by moving a precisely enhanced force (through mechanical benefit) to a material, to breakdown the bonds which keep the material intact.

Crushing is accomplished by passing the feed between two strong surfaces, then, at that point, by applying adequate power to unite the surfaces so the particles of the material being squashed are isolated from (break), or, change arrangement comparable to (misshape), one another.

Crushers are ordinarily ordered by how much they piece the beginning material, with essential and auxiliary crushers taking care of coarse materials, and tertiary and quaternary crushers decreasing particles to better degrees.

Every crusher is intended to work with a specific most extreme size of unrefined substance, and frequently conveys its result to a screening machine (screener) which sorts and coordinates the item for additional handling. Much of the time, starting squashing stages are trailed by additional processing stages (in the event that the materials should be additionally diminished); see our ball factory article for additional subtleties.

Crusher Machine Types

There are three normal crushers utilized at mining and handling plants, these plans are:

- Gyratory Crusher

- Jaw Crusher

- Cone Crusher

Crusher Types (jaw, cone, gyratory)

Regularly, the underlying squashing stage is finished utilizing either gyratory crushers or jaw crushers. It is much of the time the case that there will be just a single crusher introduced, and this will be alluded to as the 'essential crusher'.

Cone crushers are all the more frequently utilized for second, third and fourth stage crushing advances (albeit not dependably).

Cone Crusher

Jaw Crusher Parts (What makes the Jaw? and so on..)

The primary parts of a regular jaw crusher are:

- Fixed Jaw

- Moving Jaw

- Jaw Liners

- Primary Shaft (Pitman Get together)

- Drive Pulley and Flywheel

- Switch Plate(s) and Pressure Bars/Gathering

Jaw Crusher Arrangement

Jaw crushers are characterized in view of the place of the turning swing jaw. There are three fundamental jaw crusher types:

- Blake crusher - the swing jaw is fixed at the lower position.

- Evade crusher - the swing jaw is fixed at the upper position.

- All inclusive crusher - the swing jaw is fixed at a middle of the road position.

The Blake crusher was first licensed by Eli Whitney Blake in 1858 and it is the most considered normal kind of jaw crusher utilized today. The Blake type jaw crusher has a proper feed region and a variable release region. Blake type crushers come in different sizes and are regularly utilized for essential and optional pounding jobs.

How Jaw Crushers Are Estimated

Jaw crushers are estimated in view of the components of the top feed delta (expand) or the elements of the jaws. For instance, a 32 x 54 estimated jaw crusher will quantify 32 crawls from the mobile to fixed jaw (when estimated at the top for example the opening), and each jaw will have a 54-inch width. In the event that a jaw crusher is evaluated by jaw plate size, a reasonable rating perhaps 600 x 400, which demonstrates a 600 mm by 400 mm jaw plate aspect. Sizes might be given in majestic (inches and so forth) or metric (millimeter and so on.).

How Jaw Crushers Work

A Jaw Crusher involves compressive power for breaking metal pieces. Compressive power is applied by two jaws (kicks the bucket), one of the crusher jaws is fixed (fixed jaw) while the other is moving (swing jaw).

Material is taken care of into the top feed opening (expand) and progressively moves downwards towards the lower release outlet. As the materials passes towards the power source, it is squashed between the fixed and moving jaws. The angular region between the two jaws is alluded to as the 'devastating chamber'. Since the space between the two jaws becomes smaller towards the release outlet, the material size is continuously diminished.

The hole between the jaws at the release outlet directs the material result size. A commonplace Jaw Crusher will have a devastating proportion of between 6:1 to 8:1 for example the feed material size is diminished by an element of 6 or 8.

Comments

Post a Comment