Explanation of a Coal Crusher Work

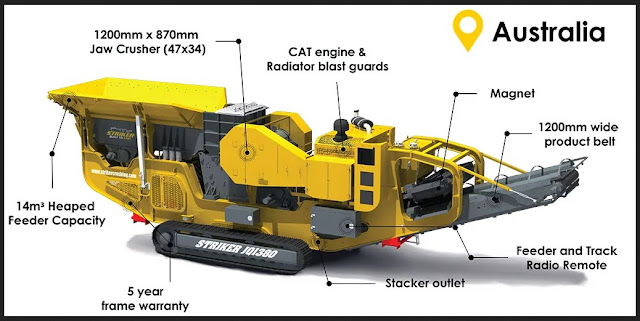

If you don't understand much about the coal crusher machine, then on this page you will briefly explain how the coal crusher works. You might work in the mining sector where the coal crusher is one of the aspects that you need to look at more deeply. Indeed, what we explain below may not answer all your questions regarding the coal crusher machine because what is explained here is only a brief description. However, at least you can conceptually understand how a coal crusher works. How does a Coal Crusher Work? A coal crusher is a machine that cycles coal into more modest pieces. It regularly consists of a progression of crushers like jaw crushers, cone crushers, influence crushers, and others. Every crusher utilizes its own cycle to lessen the size of the coal. The subsequent material is then gathered and put away in a store prepared for transport. Don't missed these: Asphalt Crusher Plant Setup Vertical Shaft Impact Crusher Mobile Jaw Crusher Plant Coal crushers, otherwise c...